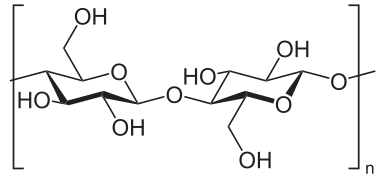

Natural Cellulose Fibers Upgrading

Catalytic Advanced Oxidation developed by Hydrogen Link finds outstanding application in the treatment and upgrading of natural cellulosic fibers extracted from plants - a traditional textile source before the age of synthetics – such as hemp, flax, jute ramie, kenaf, banana, sisal etc.

Natural fibers (bast or leaf fibers) constitute the structural features made of cellulose, which are incorporated in the soft tissue of the plant that "glues" the fibrous structure together and reinforces the strength of the stems or leafs. These tissues are made of lignins, gums, proteins, hemicellulose etc. In order to extract the cellulosic fibers, the lignins/gums have to be eliminated. The traditional methods of degumming of hemp or flax (linen) required elaborated and complicated treatment, which included prolonged “retting” – seasoning in the field in order to soften the lignins and better expose the fibers, followed by meticulous carding, combing, cleaning and softening.

The modern techniques try to replace the complicated, labor-intense treatment of the fibers by harsh chemicals – boiling in hot, concentrated alkaline or acidic concoctions under pressure. The results are not only polluting the environment (and thus offsetting the advantages of the use of natural fibers) but usually also damage the cellulose and weaken the fibers because of the aggressive chemical treatment.

The method of Catalytic Advanced Oxidation revolutionizes the bast fiber upgrading by using hydrogen peroxide (H2O2) combined with our Oxycatalyst to obtain clean, white natural cellulose fibers - through oxidative elimination of the non-cellulosic parts of the plant: lignins, gums, pectins, hemicellulose. This part of the upgrading process is usually called (“degumming” or "delignification"). Further treatment can refine the fibers even more – by separation the single cellulosic strands, which can even reach the softness and feel of cotton – which is called “cottonization”.

Hydrogen Peroxide is the most environmentally friendly chemical of all, because it decomposes into water and oxygen, without any other byproducts being added by H2O2. In combination with our unique solid-state catalyst, it is able to fully upgrade - degum and cottonize all types of bast and leaf fibers. Our catalyst is heterogeneous (in a solid state) so it does not dissolve in the effluent, and it thus stays behind and can be reused. The process can be performed at neutral pH and at room temperature. It does not require expensive instrumentation such as stainless steel autoclaves needed to withstand the commonly used aggressive chemicals at high temperature and pressure.

Therefore - in terms of the environmental impact of the Natural Fibers processing - the Catalytic Advanced Oxidation with hydrogen peroxide is unique in its ZERO POLLUTION capability.

Please contact us with inquires related to cooperation and purchase of our catalysts: Contact for Inquiry or contact@hydrogenlink.com

Read more: Hemp and Flax Bast Fibers

The Catalytic Advanced Oxidation is capable of full degumming and delignification of fiber-bearing plant (bast fiber or leaf fiber), thus resulting in the clean cellulose fibers of high quality. This process imitates the natural degradation of bast plant ("retting"), which involves microbial removing of lignins, pectins, gums and hemicellulose in the natural environment. In this process, the "softer tissue" of the plant is being degraded preceding the decomposition of cellulose fiber, since cellulose has a strong, compact structure and is therefore more difficult to oxidize. Following the "delignification", the oxidative process of decomposing organic matter (if carried out further) is subsequently directed towards degrading the cellulose - both in nature and with the use of the process of Catalytic Advanced Oxidation.

This selectivity feature of Catalytic Advanced Oxidation represents the principal advantage in comparison to the typical "etching" processes with harsh chemicals, which are based on aggresive corrosion of lignins and gums alongside with cellulose.

In practice, our treatment of bast fibers is very flexible: it can be done on unretted, fresh plants, without preparation such as decortication (i.e. separating bast from hurd) or field- or water seasoning. Alternatively, it can be performed as a finishing step on pre-prepared, mechanically cleaned, decorticated and retted bast strips of raw fibers.

One such example is the extraction of clean hemp fibers from the whole plant stems without neither mechanical or chemical separation of bast. As a results, both cottonized, lignin-free hemp fibers and clean hurd material is obtained.

Cellulose pulp treatment

Alternative sources of cellulose to replace wood pulp are one of the major ecological challenges for the pulp and paper industry. Cellulose from straw (for example wheat straw or bagasse - sugar cane cellulose) is a waste material that can be used for paper production, as well as all types of natural fibers (hemp, flax, jute, kenaf, sisal, banana, ramie).

The advantages of such cellulose sources are essential: yearly growth cycle and sustainability exceeding wood cellulose, easier availability and adaptation to various growth conditions.

However, the processing of straw is actually not much easier than processing wood because of high amount of stubborn lignins (thus making the delignification of straw difficult). Especially the whitening (bleaching) of these lignins is troublesome, because the common bleaching methods which employ harsh alkaline treatment actually give the chromophores in straw lignins even more intense colors - brown or deeply yellow, instead of the whitening.

By contrast, Catalytic Advanced Oxidation is very effective in treatment (degumming, delignification and whitening) of not only all types of natural fibers (bast and leaf fibers -hemp, flax, jute, kenaf, sisal, banana) but also the cellulosic materials in grass, straw, bagasse.

This processing opens new prospects for pulp and paper production - with ecological advantage of the yearly turnout of the cellulose plants and ZERO-POLLUTION treatment.

Microcellulose

Micro-scale cellulose particles have a variety of uses in many industries - food, beverage, cosmetic, pharmaceutical, plastic composites. Microcellulose can be used as binder, stabilizer, thickener, emulsifier. The critical aspect of these applications is the quality of microcellulose, which needs to be 100% pure and without any residues of the non-cellulosic material of the plant. The use of concentrated acids or other harsh chemical can achieve that but with dramatically reduced practical yield in such processing because a significant amount of cellulose is etched away. The ability to extract pure cellulose with much better yield from all kinds of cellulosic plants is of great advantage, especially when the eco-friendly approach allows for the elimination of pollution in the processing wastewater, as well as

Catalytic Advanced Oxidation uses only hydrogen peroxide H2O2 in the degumming and delignification of cellulose fibers manufacturing of microcellulose.

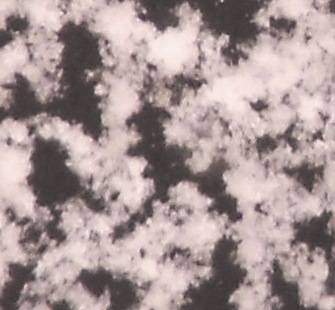

Cottonized Fibers under Microscope

Cotton - right

"Cottonization" is the process of cleaning, degumming, delignificaion and softening of natural fibers in order to bring them as much as possible to the properties of cotton - to be able to use them in textile products either alone or in combination with cotton. These processes cannot change the intrinsic properties of the various plant fibers (their natural length and diameter) but removing the lignins which glue the fibrils together within the strand/bundle gives the opportunity to widen the possible applications of these fibers.

Processing of natural fibers by Catalytic Advanced Oxidation can be carried out toward delignification to the required level of cottonization, i.e. to the optimum level of softness vs. strength. If needed, single cellulosic fibrils of hemp, flax or jute can be extracted from their bundles in the plant and separated through elimination of the gums and lignins.

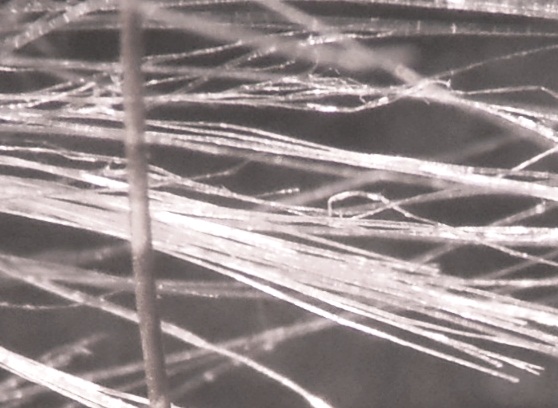

The micrographs show a comparison between cotton fibers (in the right part of the photograph) and the fully cottonized jute fibers. The following pictures show microscopic views of the single fibrils of hemp in comparison with human hair (in front of the fibers).

Read more: Hemp and Flax Bast Fibers

Please contact us with inquires related to cooperation and purchase of our catalysts: Contact for Inquiry or contact@hydrogenlink.com

Bleaching of cellulose

Processing of cotton - from fiber to textile- involves many stages. An important step called "sizing" is needed to improve the fiber strength and resilience during yarn weaving. It is based on covering the cotton with various chemicals and waxes which improve the operation of machinery and reduce waste. The "sized" fibers as well as the resulting textiles, while reinforced, exhibit also strong hydrophobic properties, which prohibit subsequent dyeing and reduce the fabric softness. Sizing introduces also a characteristic beige color to cotton, which needs to be eliminated before dying or using it as a white cotton fabric. The "sized" cotton is also called "greige cotton" or grey cotton.

Catalytic Advanced Oxidation can be effectively used for "desizing" of the cotton fiber or greige cotton. It can entirely remove the chemical layer of the "size", as well as restore and improve whiteness of cotton. The processing is done at room temperature, without any harsh chemicals. The process is in practice "zero polluting", because it is based on the use of hydrogen peroxide and as a result no additional waste chemicals are introduced to the process and to the wastewater.

Natural Precursors for Carbon Fibers

Natural bast fibers can represent an ecological source for the Carbon Fibers processing, if they can be perfectly degummed and cottonized. Catalytic Advanced Oxidation developed by Hydrogen Link can provide such high quality of cellulose strands, which may become ultra thin carbon fiber precursors. The micrographs below show carbon fiber precursors obtained from hemp cellulose fiber after full degumming and cottonization. The right picture shows for comparison a human hair in front of the fibers.

Please contact us with inquires related to cooperation and purchase of our catalysts: Contact for Inquiry or contact@hydrogenlink.com

Read more: Hemp and Flax Bast Fibers

Read more: Catalytic Advanced Oxidation, Hydroxyl Radicals Reactivity, Organic Matter Degradation, Wastewater treatment, Dye decoloration and degradation, Oxycatalyst, Oxygen Generation

Cotton bleaching with hydrogen peroxide

Cotton twine bleached by catalyzed hydrogen peroxide

Hemp fibres

Hemp fibre upgrading with catalyzed hydrogen peroxide

Bleaching and upgrading jute fibres

Jute fibre bleaching and upgrading

Sisal (agave) fibers bleaching and upgrading

Natural fibers (sisal) refining by advanced oxidation with catalytic decomposition of H2O2

Read more: Hemp and Flax Bast Fibers

Read more